Practical advice

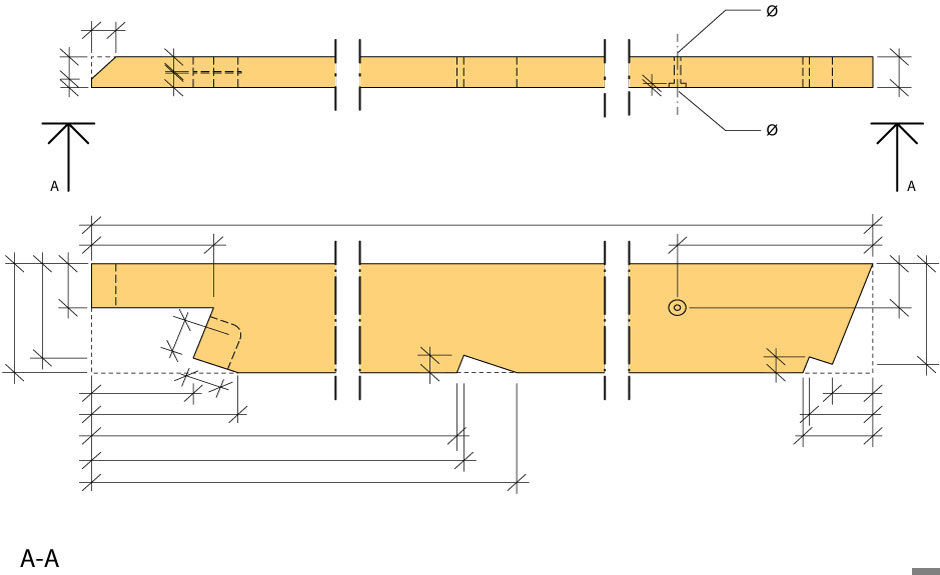

Specifications on the drawings

Camber

Storage and handling

Glulam stored on the construction site should be covered with a tarpaulin or given equivalent weather protection. The plastic packaging does not provide protection against the weather.

Glulam should only be stored on site for a limited period.

Stacks should be stable with a sufficient number of supports and designed so that the glulam is protected from ground moisture, rain and snow and direct sunlight.

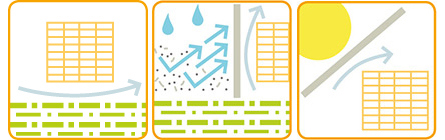

Protect the glulam

- Against precipitation

- Against sun

- Against dirt

- Against ground moisture

- Never lay glulam directly on the ground.

- Do not place glulam where there is a risk of soiling, for example splashing from roofs or traffic.

- The ground should be cleared of snow.

- Make sure the storage place is in shade during spring, summer and autumn. Glulam surfaces in sunlight will become warmer than the ambient temperature, which can lead to cracks or condensation. This then increases the risk of microbial growth.

- Use clean battens, at least 300 mm above the ground or floor, with good air circulation. Make sure there are enough battens to prevent the glulam from bending.

- Place clean spacers between the glulam elements and place the spacers vertically above each other.

- When storing outdoors, protect the glulam with tarpaulins, for example, that are placed on clean battens to ensure good ventilation under the tarpaulin. Make sure the tarpaulin is not touching the glulam anywhere. Do not allow the tarpaulin to reach the ground.

- Avoid lengthy storage outdoors on the construction site.

- Use foundation battens and make sure the ground is well drained.

- Protect against dirt

- Protect against sun

- Protect against precipitation

- Keep timber for exterior use ventilated and protected.

- Glulam for indoor use should be stored indoors.

Example of how glulam may be stored for a short while on site

Assembly

Things to bear in mind during assembly

- Check the moisture content and surface moisture content before using the glulam product, and check that there is no microbial growth.

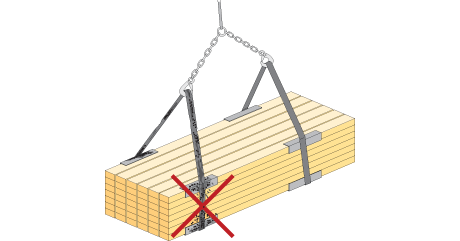

- Use wide, clean straps during crane lifts and protect the edges of the glulam with angled brackets or other edge protection, so that no lift marks occur.

- Ensure that gloves, straps and other lifting devices are clean.

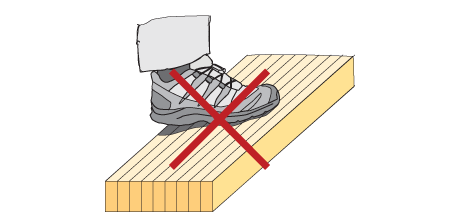

- Do not walk on surfaces that will be visible after assembly.

- Take all necessary measures to secure the frame against wind and other stresses during the construction phase.

- Fix the glulam products in the right position until the structural frame has been stabilised.

- Leave the packaging in place after assembly as protection against dirt and precipitation during the construction period.

- Structural fixings made from hot-dip galvanised steel plate and anchor nails or anchor screws are recommended for use in assembly. Builder’s merchants and timber merchants carry various types of standardised fixings.

- Check that the surface moisture content is no more than 18% if encasing the glulam, and 16% if painting. Perform random tests using an electrical resistance moisture meter.

Check the moisture content

Do not step on the glulam product.

Use clean gloves, straps and edge protection during crane lifts.