From raw material to wood product

Spruce and pine pulpwood on the left and pine saw logs on the right, stacked for collection.

Spruce and pine pulpwood on the left and pine saw logs on the right, stacked for collection.

Harvesting

When a tree is ready for harvesting it is felled, debranched and usually cut into a butt log, middle log and top log, plus one to three sections of pulpwood. Crown and branch wood can be collected up to be chipped and used as forest fuel. Smaller trees that are felled during thinning, for example, are cut into pulpwood or small-dimension saw logs with a top diameter of 120–200 mm. See fig. 14.

Sawmills

Sweden currently has around 130 sawmills, each of which produces over 10,000 cubic metres (m3) of sawn wood products per year. Production is being concentrated among ever fewer companies, with individual sawmills specialising in wood types and product groups. Of the total production in Sweden – around 18.6 million cubic metres (mn m3) sawn wood products (2019) – the 10 biggest companies account for around 60 percent and the 20 biggest companies account for around 80 percent of the country’s production. Alongside the industrial sawmills is the smaller-scale production for local and domestic purposes at a number of small sawmills.

Different cutting methods are used at the sawmills. The circular saw dominates among the small sawmills, while reducer band saws and reducer circular saws are most common in larger sawmills. The reducing process mills away the circular segments outside the rectangle, which is then divided up into planks and boards using band or circular saws.

Fig. 18 Example of square sawing with centrecut, 2 ex-log (Nordic sawing practice)

Fig. 19 Example of square sawing, 3 ex-log

Fig. 20 Example of square sawing with centrecut, 4 ex-log (Nordic sawing practice)

Fig. 21 Example of square sawing, 5 ex-log

Profiling saws cut a profile out of the log cross-section, and then circular saws divide the planks and boards up into different sectional dimensions. Profiling saws are very much on the up, with older sawmill methods becoming less common. See also Surface structures in Quality and range.

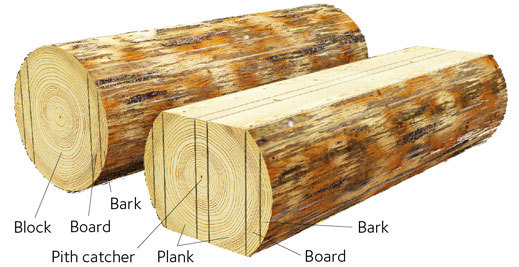

The flow from log to finished products is shown in fig. 16. The sawmill makes use of the whole log.

The most common method of sawing coniferous softwood is block-sawing, followed by resawing. With block-sawing, the log is rotated to the best position and sawn through to make optimum use of the log’s dimensions. It is then laid down so the centrecut can be sawn into boards and planks. The sawn timber (planks and boards) is given a rectangular cross-section, except for the outermost boards, which have a certain wane edge, which means that the edge is rounded instead of being sharp. Wood from the inner part of the log is the main yield, while wood from the outer parts is called side boards.

Sometimes the wood nearest the pith is sawn out with a pith catcher. This removes the less dense pith or juvenile wood from the main yield.

The moisture content (see section on Moisture content, page 36) of the freshly sawn wood varies between 30% and 160%. In order for this wood to be stored without loss of quality, it is dried to the target moisture content of 16%. Sooner or later, undried wood will be subject to microbial attacks, such as blue stain, mould or rot.

Wood tends to be dried at the sawmill to the target moisture content required for the intended end use. See Moisture in wood.

Fig. 22 Example of square sawing with pith catcher

Fig. 23 Example of sawing with pith catcher

Exports

Of the 18.6 million cubic metres of sawn softwood products manufactured in Sweden (annual average over the past 10 years), the domestic market consumes around 5.7 million cubic metres. The remainder, about 12.9 million cubic metres or around two-thirds, is exported to other countries. The exported wood is sold packaged in particular dimensions and lengths.

Consumption of softwood products in Sweden

Sweden consumed around 5.7 million cubic metres of sawn softwood products in 2018. Almost all of this came from Swedish sawmills, with less than 180,000 cubic metres imported. The timber is used for a wide range of purposes.

- The largest of these is renovations, conversions and extensions, which account for 37 percent of wood product consumption and cover both DIY and professional projects. Distribution to these customers is almost exclusively through builders’ merchants. This category of use has grown in recent years and represents an increasing proportion of Sweden’s total wood consumption. All the types of wood products used for renovations and extensions are included in this category: everything from construction timber, including pressure-treated timber, to various types of interior products.

- The second largest area of use is newbuilds. 23 percent of the wood consumed goes to this category, which only includes buildings requiring planning permission. Prefabricated houses are a large consumer of wood, but more and more is also being used for tall buildings with a wooden structure. New public buildings such as halls, schools, offices and so on are another area that is consuming increasing amounts of wood. Mass timber elements such as cross laminated timber (CLT) and glulam are a growing product category that features mainly in this area. It is estimated that the glulam and CLT industry consumed around 3 percent of Sweden’s total wood consumption in 2018. In addition to the timber used for the actual wooden frame, the category also includes wood used for internal details in new buildings such as skirting, flooring, stairs and doors.

- Wood packaging and pallets are also major consumers of timber, accounting for around 17% of overall consumption. These products include cable drums, pallets, packing crates and specialist packaging for industries that need to transport glass, ceramics, engines, vegetables and other bulky or fragile products.

- The farming sector is a relatively large consumer of wood. Because agricultural buildings are not subject to planning permission, the data is somewhat unclear, but the farming sector is believed to consume around 7 percent of the nation’s wood products.

- Construction of other buildings not subject to planning permission, including bridges, jetties, outbuildings such as cabins and garden buildings, and so on, are thought to consume around 6 percent of wood products.

- In terms of total sales, the civil engineering sector consumes small volumes of wood products, although it does still account for 7 percent of total consumption. This includes formwork for concrete structures, scaffolding and many other small-scale areas of use.

- The category of furniture and other processed products for export mainly relates to interior fittings and parts of fittings that are not a fixed part of the building structure. It also includes processed products that are exported from Sweden and therefore do not fall into any of the other areas of use.

Of the total sales of wood products in Sweden, it is estimated that just over 3 million cubic metres or around 55 percent is sold via builders’ merchants. Of this, 13 percent or 720,000 cubic metres is pressure-treated for the Swedish market.

Fig. 24 Consumption of softwood products, million cubic metres, in Sweden. Estimated.

Vattenpalatset, Lerum.

Vattenpalatset, Lerum.